The Whistling Enamel Kettle is a common household appliance known for its distinctive sound that signals when water has reached boiling point.

The Whistling Mechanism Explained

The whistling mechanism in a Whistling Enamel Kettle relies on a combination of steam dynamics and sound production. When water inside the kettle boils, it generates steam, which builds pressure and exits through a specially designed spout, creating the familiar whistle. This process involves several key aspects that ensure efficiency and reliability.

The Role of Steam Pressure

Steam pressure is the driving force behind the whistle in a Whistling Enamel Kettle. As heat is applied, water evaporates and turns into steam, increasing the internal pressure within the enclosed kettle. This pressure seeks an escape route, typically through a narrow opening or whistle device attached to the spout. The design ensures that steam flows in a controlled manner, leading to the production of sound.

-

Pressure Buildup: When the water boils, steam accumulates in the upper part of the Whistling Enamel Kettle, raising the pressure above atmospheric levels.

-

Ventilation Path: The kettle's spout is fitted with a whistle component that acts as a valve, opening only when sufficient pressure is reached to force steam through it.

Acoustic Principles of the Whistle

The sound in a Whistling Enamel Kettle is generated through acoustic vibrations caused by the flow of steam. As steam passes through the whistle's narrow aperture, it creates oscillations that produce audible frequencies. This is similar to how musical instruments like flutes work, but tailored for a practical alert system.

-

Vibration Generation: The steam stream interacts with edges or chambers in the whistle, causing rapid pressure fluctuations that result in sound waves.

-

Frequency Control: The pitch and volume of the whistle depend on factors such as the size and shape of the whistle opening, as well as the steam flow rate, which are optimized in a Whistling Enamel Kettle for clear audibility.

Key Components of the Whistling Enamel Kettle

To understand how the whistling mechanism functions, it is essential to examine the main parts involved. A standard Whistling Enamel Kettle includes components designed to handle heat and pressure while producing sound.

-

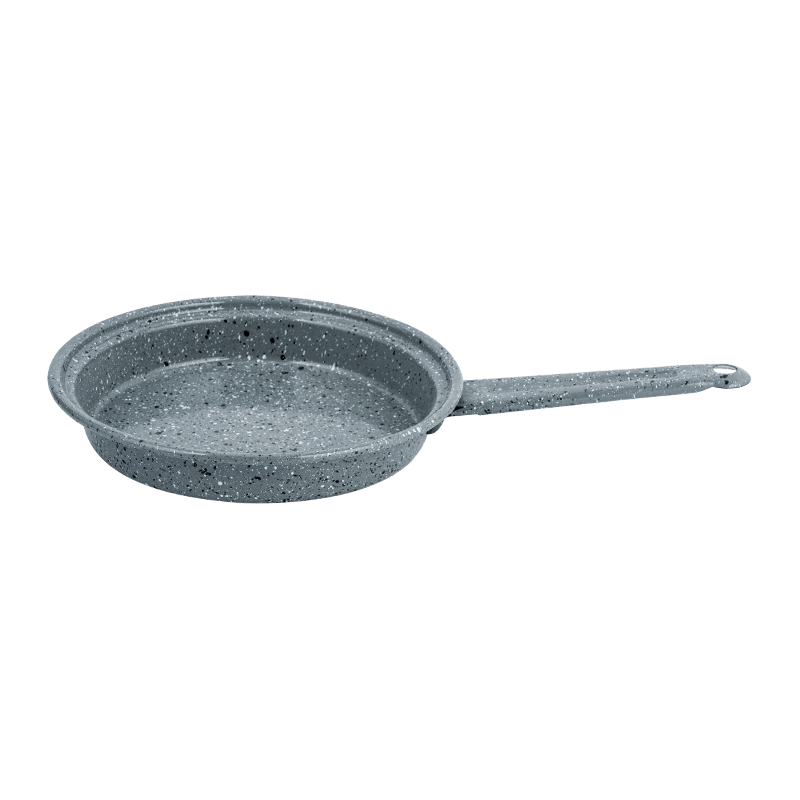

Enamel-Coated Body: The kettle's exterior is often coated with enamel for durability and heat resistance, ensuring safe operation during boiling.

-

Whistle Assembly: This typically consists of a metal or plastic device attached to the spout, featuring a small hole or reed that steam passes through to create vibrations.

-

Lid and Seal: A tight-fitting lid prevents steam from escaping prematurely, directing it toward the whistle for efficient sound production.

-

Handle and Base: Ergonomically designed for safety, these parts allow users to handle the Whistling Enamel Kettle without direct contact with hot surfaces.

How the Whistling Process Works Step by Step

The operation of a Whistling Enamel Kettle can be broken down into a sequential process, from heating to sound emission. Each step is crucial for the reliable performance of the whistling mechanism.

-

Heating Phase: The kettle is placed on a heat source, and water inside begins to absorb energy, gradually increasing in temperature.

-

Steam Generation: As the water reaches boiling point (100°C or 212°F at sea level), it produces steam that rises and accumulates in the kettle's upper chamber.

-

Pressure Escalation: The steam builds pressure until it exceeds the threshold required to open the whistle valve, typically a few kilopascals above ambient pressure.

-

Sound Production: Steam rushes through the whistle, where it encounters obstructions or resonating chambers, generating vibrations that emit a whistling sound.

-

Automatic Alert: The whistle continues as long as boiling persists, serving as an audible indicator to turn off the heat source, thus preventing over-boiling or damage to the Whistling Enamel Kettle.

The whistling mechanism in a Whistling Enamel Kettle is a well-engineered system based on fundamental principles of physics and acoustics. By leveraging steam pressure and vibrational dynamics, it provides a reliable and non-electric method for signaling when water has boiled.

English

English 中文简体

中文简体