The humble cooking pot is a foundational tool in human civilization, evolving alongside our culinary practices and technological capabilities. Among the diverse array of cookware, the Double Handle Enamel Pot occupies a unique and enduring space. It stands as a testament to the marriage of robust industrial materials with delicate, artisanal craftsmanship, resulting in a vessel that is simultaneously utilitarian, aesthetically pleasing, and deeply resonant with cultural history. More than just a container for boiling or stewing, it represents a specific solution to culinary challenges, embodying principles of durability, heat management, safety, and visual charm. This exploration delves deep into the concept, history, manufacture, properties, uses, and cultural significance of this iconic piece of cookware.

1. Defining the Concept: What is a Double Handle Enamel Pot?

At its core, a Double Handle Enamel Pot is a cooking vessel characterized by two primary features:

- Enamel Coating: An intensely durable, glass-like layer fused at high temperatures (typically 800-900°C / 1472-1652°F) unto a base metal, almost exclusively carbon steel or cast iron. This vitreous enamel coating is composed of finely ground glass minerals (frit) suspended in a liquid medium, applied via spraying or dipping, and then fired. The result is a non-porous, exceptionally hard, and chemically inert surface.

- Dual Handles: Symmetrically placed handles, typically one on each side of the pot, made either from the same enameled steel/iron as the body (formed during pressing/casting) or from a separate heat-resistant material like phenolic resin (Bakelite) or stainless steel, securely riveted or clipped on.

This combination defines its essence:

- Functional Purpose: The double handles provide balanced lifting and carrying, essential for maneuvering a heavy, potentially hot, and liquid-filled vessel. They distribute weight evenly and offer secure grips from multiple angles, reducing the risk of spills and burns associated with trying to tilt or pour a heavy pot with a single handle.

- Material Advantage: The enamel coating transforms the reactive base metal (prone to rust and interaction with acidic foods) into a supremely hygienic, easy-to-clean, and non-reactive cooking surface. It prevents rust, eliminates metallic taste transfer, and provides a smooth barrier against food sticking (though not inherently non-stick like modern coatings).

It's distinct from:

- Single-Handle Saucepans: Designed for sauteing and quick maneuvering, unsuitable for large volumes or heavy contents.

- Raw Cast Iron Pots (e.g., Dutch Ovens): Require seasoning, are reactive, and prone to rust without meticulous care.

- Stainless Steel Stockpots: Highly durable and non-reactive, but lack the enamel's unique non-porous glass surface and often the distinctive aesthetic.

- Ceramic/Clay Pots (e.g., Cocotte, Donabe): Offer different heat properties and aesthetics but are generally more fragile and often lack robust handles.

The Double Handle Enamel Pot occupies a specific niche: it's the workhorse for large-volume wet cooking (boiling, stewing, braising, soup-making, canning) where easy handling, hygienic properties, and durability are paramount, coupled with an enduring aesthetic appeal.

2. A Journey Through Time: Historical Origins and Evolution

The story of the enamel pot intertwines with the histories of metallurgy, glassmaking, and domestic life.

- Ancient Precursors: The concept of vitreous enamel (glass fused to metal) dates back millennia, seen in Egyptian jewelry, Celtic artifacts, and Byzantine religious icons. However, applying this to utilitarian cookware was impractical until industrial advancements.

- Enameling Breakthroughs (18th-19th Century): The foundations were laid with discoveries enabling the production of thinner, more durable enamels suitable for larger surfaces. Crucially, the development of resilient, low-expansion enamels compatible with steel substrates in the mid-19th century (particularly in Germany and Austria-Hungary) was pivotal. Early industrial enameling often suffered from chipping and poor adhesion.

- Rise of Industrial Enamelware (Late 19th/Early 20th Century): Technological refinements in steel production (Bessemer process, open-hearth furnaces) provided affordable, consistent sheet steel. Simultaneously, enameling processes became more controlled and efficient. Companies across Europe (Germany's "Emaille," France's "Cristel," Scandinavia's "Rosti," Russia's "Kuznetsov") and later North America (Graniteware, Agateware) began mass-producing enameled holloware – bowls, buckets, basins, and crucially, pots.

- The Double Handle Emerges: While early enamel pots existed with single handles or bail handles (wire arches), the double-handle design became dominant for larger capacity pots (generally 3 quarts/liters and up). This addressed a fundamental ergonomic need: safely lifting and transporting heavy, hot liquids. The design was pragmatic, born from the necessity of handling cumbersome vessels in domestic kitchens, communal settings (canteens, farms), and even military field kitchens. Its simplicity and effectiveness ensured its persistence.

- Material Shift: Early versions often used thinner sheet steel. Cast iron enameled pots (like the famed French "Cocotte en Fonte") developed alongside, offering superior heat retention but greater weight. The double-handle design proved essential for both types, especially the heavier cast iron.

- Golden Age and Utility: The first half of the 20th century marked the golden age of utilitarian enamelware. Double handle pots became ubiquitous in households worldwide. They were durable, affordable, easy to clean, and brightly colored, adding a cheerful touch to often austere kitchens. They were essential for large-scale food preparation, preserving, and everyday cooking.

- Post-War Evolution & Cultural Icons: Post-WWII, designs became sleeker, colors more varied. Specific manufacturers became iconic. Le Creuset's colorful cast iron cocottes, introduced in the 1920s but gaining global fame later, often feature double "loop" handles. Similarly, brands like Falcon Enamelware (UK) maintained the classic double-handled steel pot design. In Eastern Europe and Russia, robust enamel pots ("Эмалированная посуда") became a staple of Soviet domestic life, renowned for their durability and distinctive patterns (often white with blue or grey speckles, or floral motifs). The Japanese "Nabe" tradition also utilizes enameled steel pots with double handles for communal hot-pot cooking.

- Modern Resurgence: While facing competition from stainless steel and non-stick alternatives in the latter 20th century, the double handle enamel pot has experienced a significant resurgence. Driven by nostalgia, appreciation for durable goods, the popularity of slow cooking (braising), and a desire for aesthetically pleasing kitchenware free from synthetic coatings, modern manufacturers offer updated classics alongside vintage reproductions.

3. The Alchemy of Creation: Manufacturing Process Unveiled

Creating a high-quality double handle enamel pot is a complex, multi-stage process demanding precision and expertise:

-

A. Base Metal Forming:

- Sheet Steel Pots: High-quality, low-carbon sheet steel is precisely cut. The body is formed using deep-drawing presses that forcefully shape the flat disc into a pot shape (bottom and sides) in one or more stages. Trimming removes excess metal. Handles are either formed integrally from the sheet during pressing (common on classic designs) or prepared as separate steel components.

- Cast Iron Pots: Molten iron is poured into intricate sand molds shaped like the pot body and its handles. After cooling, the rough casting ("green casting") is removed. It undergoes "fettling" – grinding, sandblasting, or shot blasting – to remove excess material (gates, risers) from the mold and achieve a smooth, uniform surface essential for enamel adhesion.

-

B. Surface Preparation (Critical): The metal surface must be immaculately clean and microscopically rough.

- Cleaning: Degreasing removes oils and contaminants.

- Pickling: The steel or iron is immersed in a heated acid bath (usually sulfuric or hydrochloric acid) to dissolve mill scale, rust, and impurities, leaving a chemically active surface.

- Neutralizing & Rinsing: Thorough rinsing in neutralizing baths and clean water removes all traces of acid.

- Nickel Plating (Common for Sheet Steel): A thin flash coating of nickel is often applied electrochemically. This dramatically improves the adhesion and durability of the enamel layer, acting as a bonding agent and preventing rust if the enamel chips.

-

C. Enamel Application (The Art & Science):

- Slip Preparation: The enamel frit (ground glass mixture – silica, feldspar, borax, fluxes, opacifiers like titanium dioxide, colorants like cobalt or iron oxides) is mixed with water, clay (for suspension), and electrolytes to create a liquid "slip" or slurry.

- Ground Coat Application: The first, essential layer. The prepared metal piece (pre-heated or at room temperature) is dipped or sprayed with the ground coat slip. This layer, often dark blue, grey, or black (due to cobalt or nickel oxide), is specifically formulated for maximum adhesion to the metal. Excess slip is drained.

- Drying: The coated piece is carefully dried to remove moisture before firing.

- Firing: The piece enters a high-temperature furnace (typically 800-900°C / 1472-1652°F). The heat melts the glass frit particles, which fuse together and chemically bond to the metal substrate. The piece vitrifies – turns into solid glass. After firing, it cools slowly in controlled conditions (annealing) to relieve stresses and prevent cracking. This ground coat provides the foundational bond.

- Cover Coat Application (Usually 1-2 Layers): The piece is dipped or sprayed with the colored cover coat slip(s). Each layer requires meticulous drying and separate high-temperature firing. Multiple layers enhance color depth, opacity, and durability. Achieving vibrant, consistent colors demands precise control of frit composition and firing conditions.

-

D. Handle Attachment (If Separate):

- Phenolic/Bakelite Handles: Pre-molded heat-resistant resin handles are aligned and secured to the enameled pot body using hollow rivets. The rivets pass through pre-drilled holes in the pot wall and are flared or capped on the inside. Specialized gaskets or washers are often used to create a watertight seal and prevent chipping around the rivet hole. Clamped designs are less common now.

- Stainless Steel Handles: Attached similarly via rivets. The attachment points require careful sealing.

-

E. Quality Control: Rigorous inspection checks for:

- Visual defects (bubbles, pinholes, "fishscale" cracking, uneven color, bare spots).

- Structural integrity (handle attachment security).

- Adhesion testing (chipping resistance).

- Cleanliness and absence of contaminants.

- Dimension and weight accuracy.

4. Why Choose Enamel? Properties and Advantages

The enamel coating bestows the underlying metal with remarkable properties:

- Extreme Durability and Hardness: Vitreous enamel is one of the hardest materials used in cookware, rivaling quartz. It resists scratching from metal utensils far better than non-stick coatings (though abrasive cleaners or impacts can still damage it).

- Non-Porosity and Hygienic: The glass surface is completely sealed. It harbors no bacteria, odors, or flavors. It doesn't absorb liquids or residues, making it exceptionally easy to clean and sanitize. This is a crucial advantage for pots used for preserving, dairy, or acidic foods.

- Chemical Inertness & Non-Reactivity: Enamel is impervious to acids (tomatoes, wine, vinegar, citrus), alkalis, and salts found in food. Unlike raw iron, copper, or aluminum, it won't leach metals or react with ingredients, preserving the purity of flavor.

- Rust and Corrosion Resistance: The impermeable glass layer shields the underlying ferrous metal completely from moisture and oxygen, eliminating the risk of rust. This is the core reason enamel was applied to steel and iron – to make them usable with water and acidic foods.

- Easy Cleaning: The smooth, non-porous surface prevents food from bonding deeply. Stuck-on food usually releases easily with soaking. It's generally dishwasher safe (though hand washing is gentler long-term).

- Heat Resistance: Enamel withstands very high temperatures encountered in ovens, on stovetops (gas, electric, induction - if the base metal is ferromagnetic), and under broilers without degrading, peeling, or releasing fumes (unlike degraded non-stick coatings). It retains heat well, especially cast iron enameled pots.

- Aesthetic Versatility: Enamel allows for a vast range of vibrant, opaque colors and finishes (glossy, satin, speckled) that are durable and fade-resistant. It brings bright, cheerful, or sophisticated design into the kitchen.

- Food Safety: Modern, high-quality enamels used by reputable brands are formulated to be completely food-safe and free from harmful substances like lead and cadmium. They meet stringent international safety standards (e.g., FDA, EU, LFGB).

5. The Double Handle: Engineering Ergonomics and Safety

The dual handles are not mere decoration; they are integral to the pot's functionality:

- Weight Distribution: Large pots filled with liquid are incredibly heavy. Double handles allow the weight to be distributed evenly across both arms/shoulders of the user, significantly reducing strain compared to lifting with one hand or arm.

- Stability and Control: Lifting from two symmetric points provides superior balance and control when moving a full pot, minimizing sloshing and the risk of tipping or spills. This is crucial when transferring hot liquids from stove to sink or table.

- Pouring Precision: For pots designed to pour (lips), double handles offer greater stability and control during pouring, allowing for a steadier stream.

- Safety: Minimizes the risk of burns. Trying to tilt or lift a heavy, hot pot with one handle risks losing grip, leading to catastrophic spills of boiling liquid. Two handles provide secure purchase points. Heat-resistant handles (phenolic, stainless) stay cooler.

- Versatility of Handling: Allows lifting from the side or carrying like a bucket. Can be gripped by two people for very large or heavy pots.

- Structural Integrity: On large pots, attaching handles at two points distributes stress more evenly across the pot wall compared to a single handle, reducing the risk of deformation or failure over time.

- Oven Compatibility: Loop handles (common on cast iron) allow for easy insertion and removal from ovens using mitts. Side handles on steel pots also facilitate oven handling.

6. Material Considerations: Steel vs. Cast Iron

Double handle enamel pots primarily come in two base metals, each imparting distinct characteristics:

-

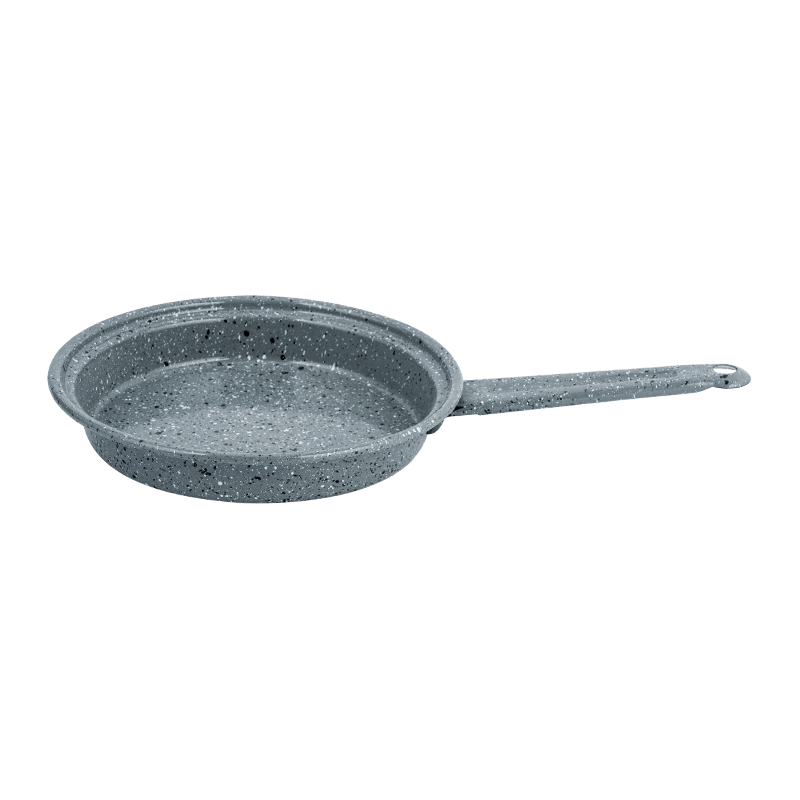

Enameled Carbon Steel (Sheet Steel):

- Pros: Lighter weight than cast iron (easier to maneuver, especially when full). Excellent heat conductivity (heats up relatively quickly and evenly across the bottom and lower sides). Generally more affordable. Classic "speckled" or "graniteware" look. Often features integral or riveted handles.

- Cons: Thinner walls mean slightly less heat retention overall compared to cast iron. Can be prone to denting if impacted forcefully. Less thermal mass for searing, though still good for boiling/stewing.

- Best For: Everyday large-volume boiling (pasta, potatoes, corn), soup-making, steaming, canning, general stockpot duties where lighter weight and faster heating are advantageous. Brands: Falcon Enamelware, Graniteware (USA), various Eastern European manufacturers, Ikea, Hario (Japan - some models).

-

Enameled Cast Iron:

- Pros: Exceptional heat retention and even heat distribution. Superior ability to hold a steady temperature for long periods (ideal for slow braising, stewing, simmering). Thick walls retain heat exceptionally well. Very durable and resistant to denting. Excellent for searing meat before braising (due to high thermal mass). Often has superior aesthetic depth.

- Cons: Significantly heavier (a major consideration when full). Slower to heat up and cool down. Generally more expensive. Requires careful handling to avoid chipping enamel on hard surfaces (weight accentuates impact force).

- Best For: Slow-cooked dishes (braises, stews, tagines, pot roasts), deep frying (excellent heat retention), baking bread (Dutch oven effect), soups where long simmering is key. Brands: Le Creuset, Staub, Lodge (Enameled), Descoware (vintage), many Japanese and Scandinavian manufacturers.

7. The Spectrum of Use: Culinary Applications

The double handle enamel pot excels in numerous cooking scenarios, leveraging its material strengths:

- Boiling: Its primary domain. Perfect for large quantities of pasta, potatoes, vegetables, corn on the cob, lobster, eggs. The non-reactive surface handles salted water perfectly. Easy cleaning.

- Soup and Stock Making: Ideal for simmering broths, stocks, and soups for hours. Non-reactive surface handles acidic tomatoes and wine. Easy to clean, even after reducing stocks. Hygienic for storage/chilling.

- Steaming: Using an inset steamer basket, it's excellent for vegetables, dumplings, seafood. Ample capacity.

- Stewing and Braising (Especially Cast Iron): The enamel cast iron double handle pot is a champion. Sear meat directly in the pot, deglaze, add liquids and aromatics, cover, and transfer to the oven or keep on low heat for tender, flavorful results. Excellent heat retention ensures gentle, even cooking.

- Deep Frying (Cast Iron): High thermal mass maintains oil temperature well when adding food, leading to crispier results. Easy to clean enamel surface.

- Canning and Preserving: Non-reactive, hygienic, easy to clean properties make it a traditional choice for water bath canning jams, jellies, pickles, and tomatoes. Large capacity accommodates multiple jars.

- Baking (Cast Iron): The covered cast iron double handle pot (acting as a Dutch oven) creates a steamy microclimate perfect for artisan bread baking, yielding crisp crusts and open crumbs. Also good for cobblers and deep-dish pies.

- Serving: Its attractive appearance, especially vibrant colored or classic speckled enamel, makes it suitable for rustic, communal tabletop serving of stews, soups, or paella-type dishes. Retains heat well.

- General Utility: Beyond strict cooking, it's useful for mixing large salads, holding ice and beverages, storing dry goods, or even as a durable planter!

8. Care and Maintenance: Ensuring Longevity

Proper care maximizes the lifespan of an enamel pot:

- Avoid Thermal Shock: Never plunge a hot pot into cold water or add cold liquid to a very hot pot. Sudden temperature changes can cause the enamel to crack or "craze." Allow pots to cool gradually before washing or adding cold water. Heat liquids gently initially.

- Gentle Utensils: Use wooden, silicone, or plastic utensils to minimize scratching the enamel surface. Avoid metal whisks or spoons aggressively scraping the bottom. Never use knives inside the pot.

- Cleaning: Wash with warm soapy water and a soft sponge or cloth. Avoid abrasive scouring pads (like steel wool) or harsh abrasive cleaners that can dull or scratch the surface. For stubborn residue, soak the pot in warm soapy water. Baking soda paste can be used gently. Most are dishwasher safe, but hand washing is gentler over decades. Dry thoroughly.

- Stain Removal: Stains can occasionally occur, especially with strong pigments like turmeric or berries. Baking soda paste or a dilute bleach solution (rinse extremely well afterward) can help. Avoid abrasive methods.

- Avoid Impact: While durable, enamel is glass and can chip if struck hard against metal sinks, faucets, or other cookware. Handle with reasonable care, especially when full. Avoid stacking heavy items inside.

- Chipped Enamel: If the enamel chips down to the metal, the exposed metal will rust. Small chips on the exterior can sometimes be touched up with food-safe enamel paint (available from manufacturers), but this is cosmetic. Significant chips on the cooking surface compromise hygiene and rust resistance; the pot should ideally be retired from cooking use, though it may still serve decorative or non-food purposes. Never cook with exposed base metal – it can leach into food and rust will spread under adjacent enamel.

- Storage: Ensure completely dry before storing. Avoid stacking other heavy pots directly inside; use pan protectors or store lids separately if possible.

9. Aesthetic and Cultural Resonance: More Than Just a Pot

The double handle enamel pot transcends pure utility:

- Visual Appeal: From the cheerful, speckled "graniteware" of classic American kitchens to the jewel-toned satin finishes of Le Creuset and Staub, to the stark white-and-blue patterns of Soviet-era pots, enamel brings vibrant color and distinctive style to the kitchen. It's both nostalgic and modern.

- Cultural Iconography: It evokes powerful associations:

- Home & Hearth: A symbol of domesticity, family meals, and sustenance.

- Durability & Heritage: Passed down through generations ("Grandma's soup pot").

- Simplicity & Authenticity: Associated with wholesome, slow-cooked food, camping, rustic living, and traditional crafts.

- Collectibility: Vintage enamelware, especially specific patterns or brands, is highly sought after by collectors.

- Regional Identity: Distinctive styles are linked to countries (French cocottes, Japanese nabe pots, Russian/Eastern European pots, Scandinavian design).

- Nostalgia: For many, it evokes childhood memories – the pot used for family gatherings, canning in summer, or camping trips. Its resurgence is partly fueled by this emotional connection.

- Artisanal Craft: Despite mass production, the enameling process retains an element of artisanal skill, especially in achieving perfect color and finish. Handles on premium pots may involve hand-finishing.

10. Market Variations and Choosing the Right Pot

The market offers diverse options:

- Capacity: Ranges from small (2-3 qt/L) saucepans (less common with double handles) to massive stockpots (20+ qt/L). Common sizes are 4qt, 6qt, 8qt for steel; 5qt, 7qt for cast iron Dutch ovens.

- Covered vs. Uncovered: Many pots are sold with matching lids, essential for braising, simmering, and baking. Lids are also enameled steel or iron, often with a knob (phenolic or stainless).

- Handle Types:

- Integral Loop Handles (Steel): Formed from the pot wall itself (classic design).

- Riveted Loop Handles (Steel/Cast Iron): Separate steel loops riveted on.

- Riveted "Side" Handles (Steel/Cast Iron): Typically riveted phenolic resin (Bakelite) or stainless steel bars. Offer a different grip.

- Cast Iron "Ear" Handles: Part of the cast piece, usually looped.

- Finishes: Glossy, Satin, Matte, Speckled ("Granite"), Solid Colors, Patterns.

- Quality Tiers: Varies significantly. Look for:

- Thick, even enamel coverage (especially inside corners/rims).

- Smooth, defect-free surface (no bubbles, pinholes, bare spots).

- Secure handle attachment (no wobble, tight rivets/seals).

- Choosing: Consider:

- Primary Use: Boiling/Stock? (Steel). Braising/Dutch Oven? (Cast Iron).

- Capacity: Match your typical cooking needs.

- Weight Tolerance: Can you easily maneuver a heavy cast iron pot when full?

- Stovetop Type: Ensure compatibility (Induction requires magnetic base - both steel and cast iron work).

- Oven Use: Check max oven-safe temp (usually very high for enamel, but handles may have limits if phenolic).

- Aesthetic Preference: Color, finish, style.

- Budget: Cast iron is generally pricier than steel.

The Double Handle Enamel Pot is far more than a simple kitchen vessel. It is the culmination of centuries of material science and manufacturing innovation, elegantly solving fundamental problems of cooking large quantities safely and hygienically. Its durability defies trends; a well-cared-for pot can serve faithfully for decades, even generations, accruing the patina of countless family meals. The enamel coating transforms reactive metal into a pristine, easy-care surface, while the dual handles provide the essential ergonomics for managing its weighty contents.

English

English 中文简体

中文简体